Dynomax, Inc. is committed to providing world-class metal finishing services. Backed by over 30 years of experience, and certifications from Nadcap NonDestructive Testing, Nadcap Chemical Processing, ISO 9001, AS9100, ITAR, we ensure the quality, dependability and affordability to tackle almost any project.

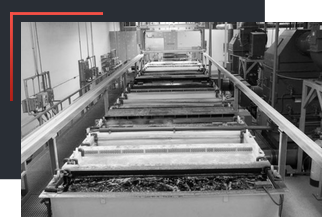

Aluminum Process Line

- Automated Crane that can handle 2 loads at one time

- AL Etch

- Chromic Acid Anodize (Type 1 and 1B) with dilute chromate seal

- Hexavalent Chromium Chemical Conversion Coatings (Class 1A and 3)

- Tank size is 30” W x 144” L x 50” Deep

Stainless Steel Line 1

- Cleaning of CRES

- Nitric Acid Passivation (~37% Concentration)

- Tank size is 24” W x 48” L x 65” Deep

Stainless Steel Line 2

- Cleaning of CRES

- Electrolytic Polishing of CRES

- Nitric Acid Passivation (AMS 2700, and more)

- Tank size is 15” W x 18” L x 18” Deep

Gold Plating Line

- Automated Crane that can handle multiple loads at one time

- Copper Flash

- Nickel Sulfamate Underplate (AMS QQ-N-290, Class 2)

- Gold (ASTM-B488, Type II, Code C)

Paint

- Paint Booth size is 14’ W x 24’ L x 9’ Tall

- Regularly stock various primers, topcoats, Teflon coats, and fuel tank coats.

- Convection Oven, 8’ W x 14’ L x 8’ Tall

NDT

- Magnetic Particle Inspection Booth (20” long max)

- Fluorescent Penetrant Inspection (12’ long max)

- Level 2 and ASNT Level 3 NAS410 Inspectors

Laboratory Capabilities

- Solution Titration and Analysis

- Salt Spray Testing (ASTM B117)

- Eddy Current Thickness

- XRF Thickness

- ICP Analysis

- UV-Vis Analysis

- Free Cyanide Analysis

- Cross-Sectioning Analysis

Nadcap Accredited